Open Ocean Fish Farming

Strength in Flexibility

When the ocean moves, fish move with it. Conventional offshore structures are designed to attenuate or resist wave-induced motions. This results in relative motions between the structure and the ocean. In aquaculture, this may have consequences for fish health in storms. From the fish’s frame of reference, nets and structures will be accelerating through their habitat requiring them to swim against accelerating flows to avoid impacts. In open ocean aquaculture, where waves can reach heights of 35m, providing a fish-friendly containment structure is not easy using a conventional steel structure.

This video shows how patented SeaStrut beams and elastic tendons can be implemented about a smaller central feed platform to deliver a fin-fish farming solution for offshore aquaculture:

Submerged containment for protection against parasites, algae and jelly-fish

Flexible net barrier to enable fish survival in highly dynamic conditions

Safe surface operating platform with surface access to submerged containment

Integration with state-of-art feed supply technologies with waste-recovery options

Embedded renewable power solutions and high autonomy

Simplified mooring hook-up and shallow draft maintenance condition for in-port net replacement and general maintenance.

Suitable for integration at floating offshore wind energy production sites

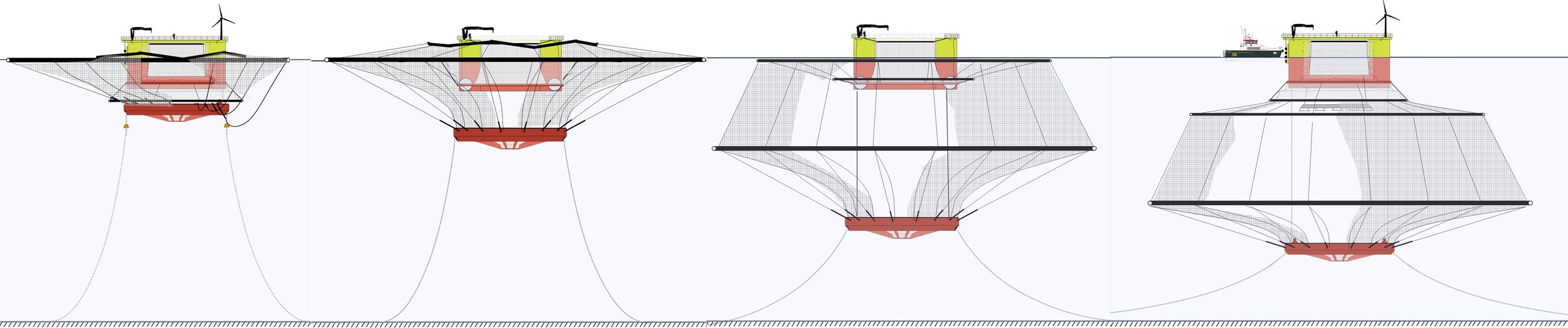

Deployment and Recovery Sequence

Net9-S

Impact-9 has already completed Front End Engineering Design on a sub-scale Net9 platform called Net9-S. This is a 10,000 m3 containment design intended to operate as a demonstration platform for potentially larger structures. Concept design of open ocean solutions of 125,000 m3 to be deployed in 60m+ water depths have been envisaged. Net9-S has been designed with the needs of salmonid species in mind and also for depth constrained regions. It could also be adapted for warmer water species and deeper ocean tension tether installations.

Interested?

Impact-9 can help your project to implement these solutions in your marine project as well as undertake suitable engineering assessments to satisfy your project stakeholders. If you would like to learn more, check out the link below or, why not reach out and let us know a bit more about your needs?